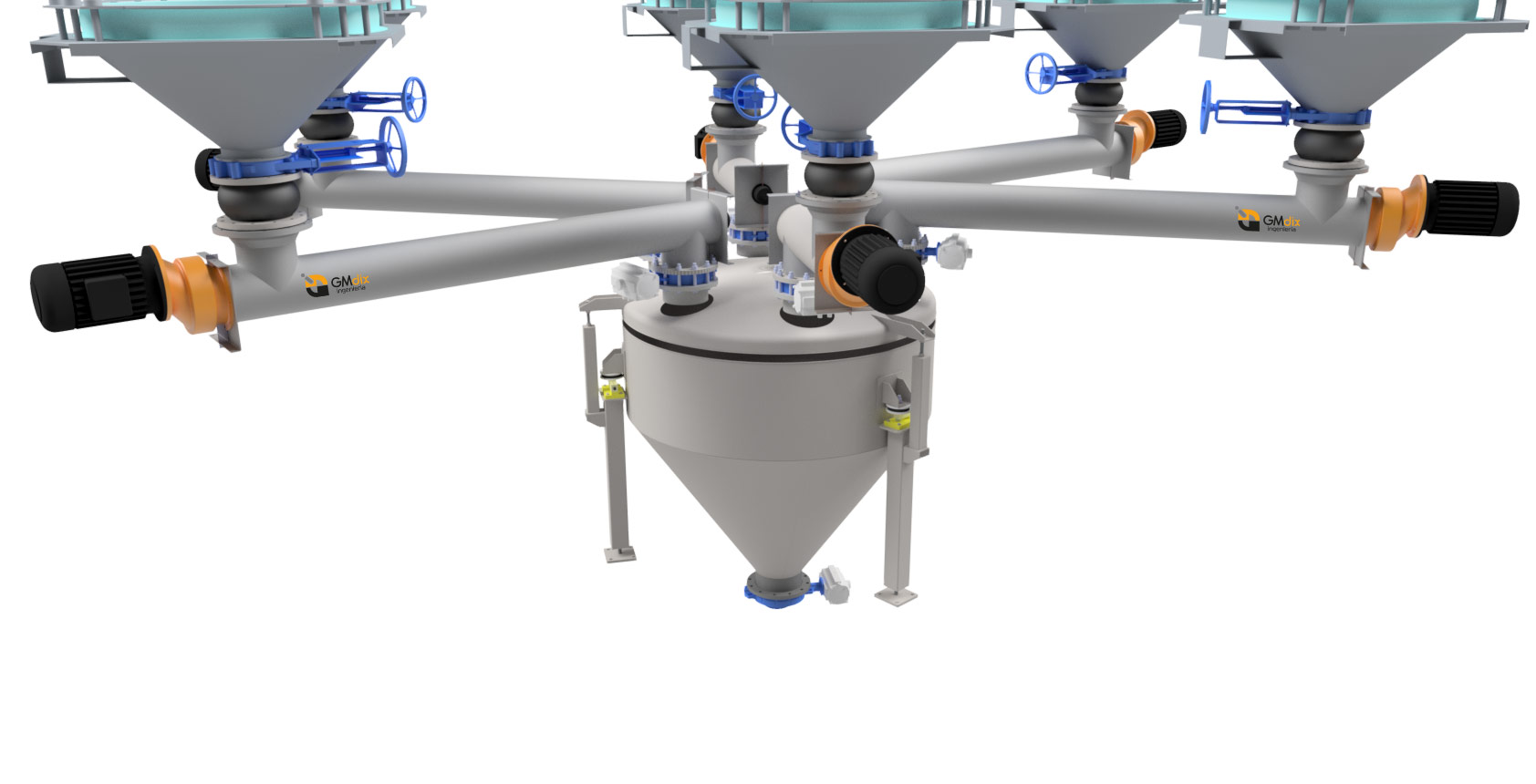

Application

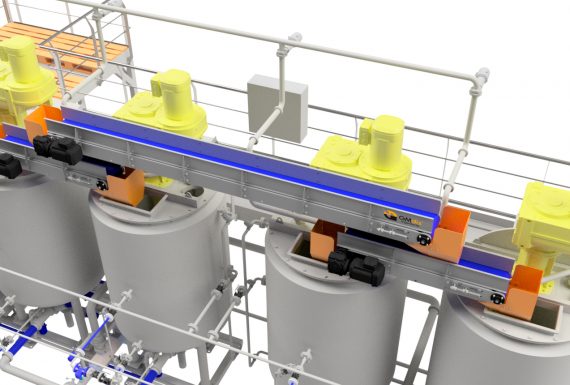

Through screw conveyors are used to convey solids for both powder and granular materials.

Through screw conveyors designed by GMdix for each project are characterised by their robustness and reliability to ensure optimal operation in any situation or need for the conveying of solids. They also have a low maintenance cost due to the quality of their materials and top international brand components. We supply through screw conveyors of any size.

Depending on requirements, various types of end bearings, shaft seals, intermediate suspension bearings, helix designs, etc. may be used.

Operation

The through screw, also known as the Archimedean screw or helical screw, is made up of a toothed blade in the form of a helix that extends longitudinally along the shaft of the screw. Between turns of each screw, a space is formed in which the materials to be conveyed are deposited, which rise or advance each time the screw turns.

To move the through screw, a motor is installed, which is in contact with its helix that makes it rotate every time the motor turns. This motor rotation transfers the movement to the through screw.

The characteristics of the through screw used in each industrial installation depend on the flow to be dosed, the type of product, the point of origin, and the discharge point.

Parts of a through screw conveyor:

1.- Conveyor (through screw)

The conveyor is comprised of a through screw, which is basically a helix wound on a central shaft that makes it rotate. The helix may be helical or sinusoidal, and is sometimes replaced with blades, depending on the materials to convey.

The helices are made up of different ridges, separated by a certain distance (known as spacing). The ridges or helices also have a diameter, which is calculated according to their intended use.

2.- Housing

The housing is the structure that surrounds the through screw and through which the materials conveyed by the screw circulate. It is normally tubular or U-shaped and has a larger diameter than the helix.

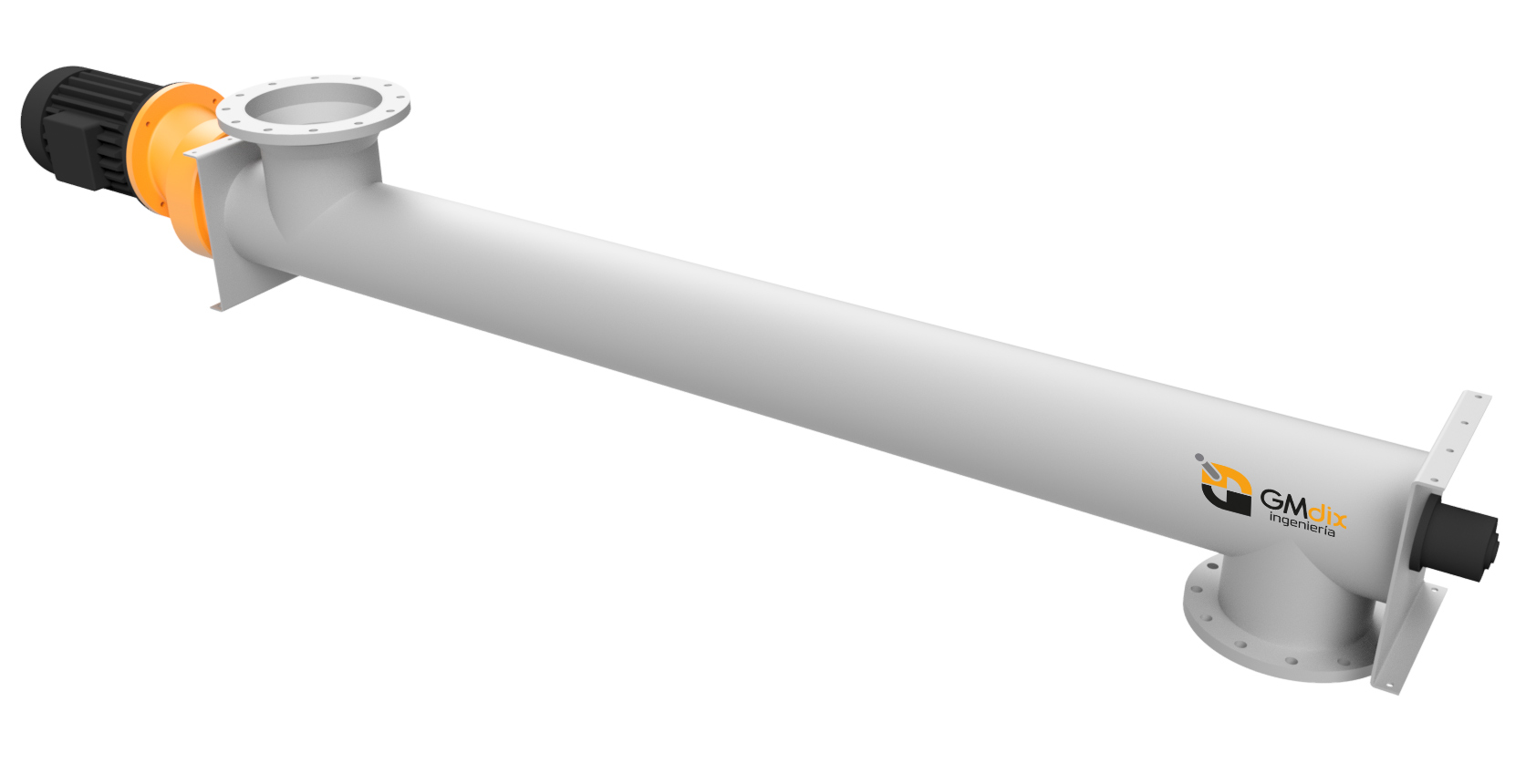

- Tubular through screw feeders and risers:

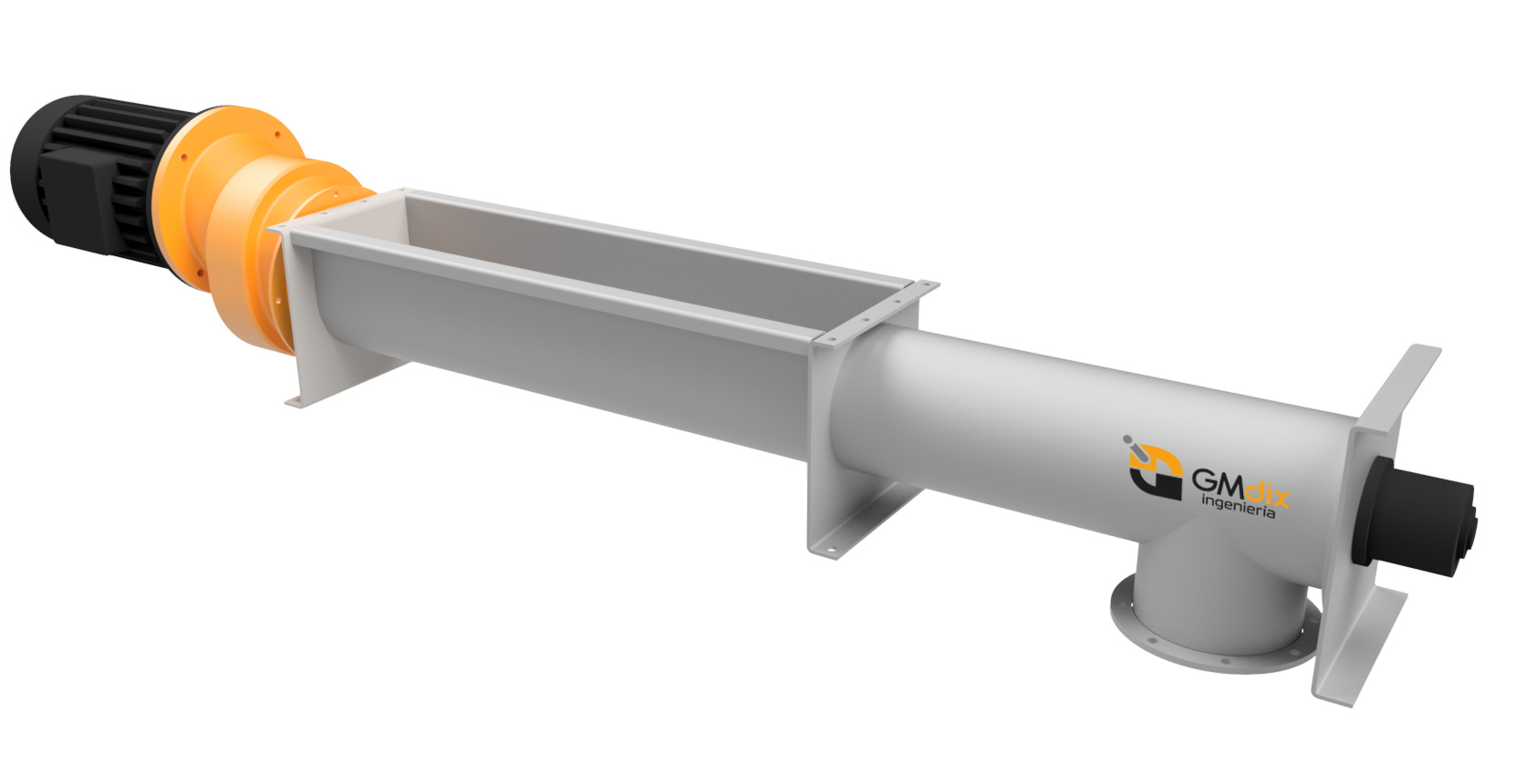

Ideal solution for dosing products at short distances. The standard measurements for this type of through screw range from Ø65 mm to Ø400 mm with lengths and designs tailored to each application. - U-type trough through screw feeders:

Ideal solution for dosing products at short and medium distances and for processes that require interior inspection of the equipment. Custom lengths and designs for each application.

3.- Motor

The electric motor is connected to the screw shaft and drives its operation. This is an electric motor with a speed reducer coupled to the housing bedplate. Motor power must be in accordance with the distance that the material must travel and the weight to convey.

4.- Hopper or loading area

Constructed in sheet metal just like the housing, this is the receptacle through which the bulk material to convey is introduced.

Technical characteristics

-

Manufactured in painted carbon steel.

-

Possibility of incorporating quick disassembly systems to facilitate cleaning.

-

Special custom designs.

-

Tubular or trough housings.

-

Intermediate supports for long distances.

-

Manufactured with different levels of finish, according to requirements.

Advantages

-

Small diameter, high efficiency, high throughput.

-

Recommended for small spaces difficult to access.

-

Easy cleaning for food applications.

-

Compact drives.

-

Silent.

-

Reliable and long durability.

-

Excellent price/performance ratio.

-

Minimal maintenance required.

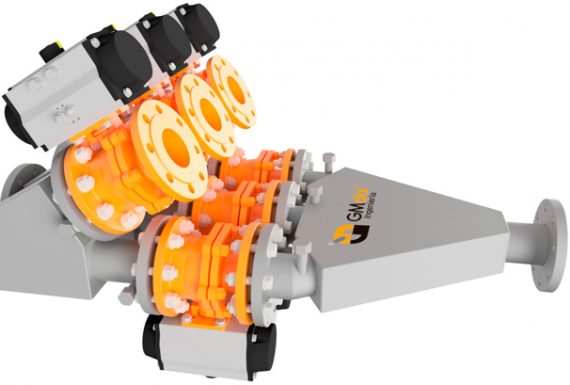

Related Products

Solids Dosing Equipment

The different dosing solutions we offer are used to ensure reliable …