Application of industrial tanks

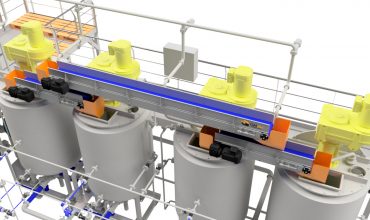

The main use of tanks is the storage of both liquid and solid products in order to maintain specific characteristics such as temperature, pressure, product homogeneity, etc. Tank dimensions are adapted to the capacities and spaces required for each client.

Operation

Tanks receive the product through one or more inlets to be stored. The product will then be conveyed to its next destination. The objective of this application is to maintain the product with the required characteristics. Therefore, element properties such as temperature, pressure, homogeneity (in the case of a mixture of immiscible products) are often taken into account. In order to ensure that these objectives are met, tanks are equipped with all types of sensors to monitor their ideal operation.

Technical characteristics

There are infinite variations given that our equipment is adapted to each client’s needs. Tanks with a capacity of 5 litres or more may be manufactured, both in carbon steel and stainless steel, with specific finishes and surface treatments for these materials. Likewise, pressure, jacketed, and heat-insulated tanks are also available, with agitators or recirculation; all of them may be combined.

Advantages

Related Products

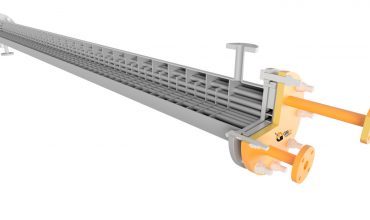

Solids Dosing Equipment

The different dosing solutions we offer are used to ensure reliable …