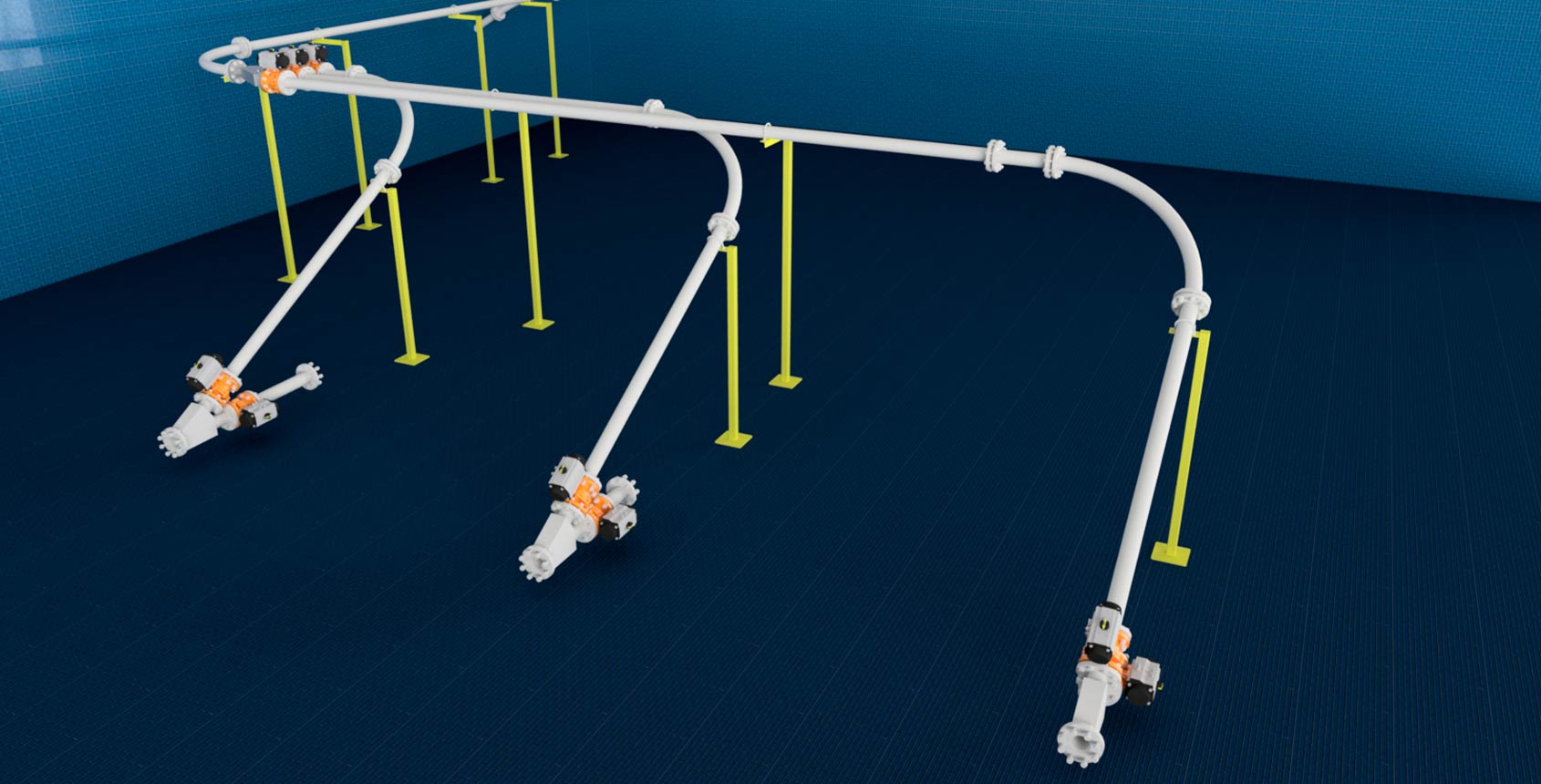

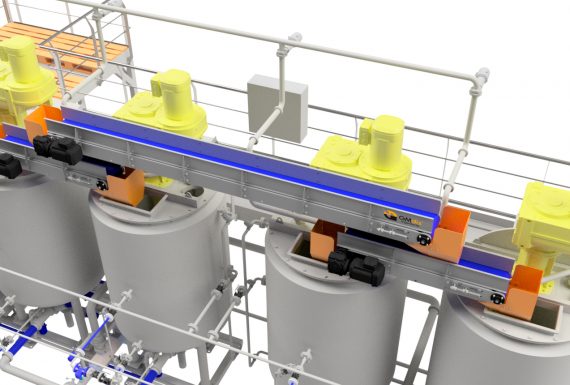

Application of diverter valves

Diverter valves are used to convert a single line into two lines or vice versa. Recommended to divert a product to different destinations.

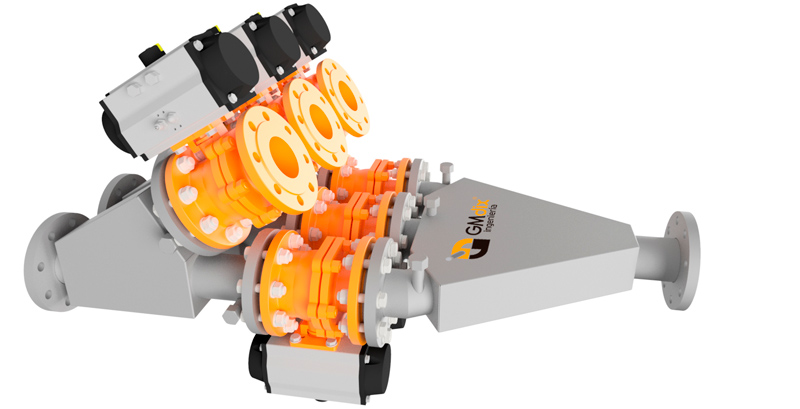

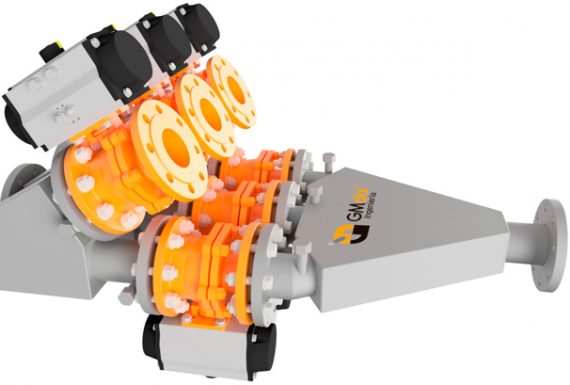

Diverter valve operation

Operation using a Y to which two valves are mounted to select the desired path by opening one valve and closing the other. It is comprised of a Y-shaped pipe and 2 sleeve or ball valves.

Advantages of Diverter Valves

Technical characteristics

There are different formats of diverter valves. These may be constructed in-house or commercially available; the latter may use rotary drums to eliminate the valves. Measurements vary according to the pipe to be used and if they are treated. They may be coated internally with anti-wear materials to minimise abrasion.