Application

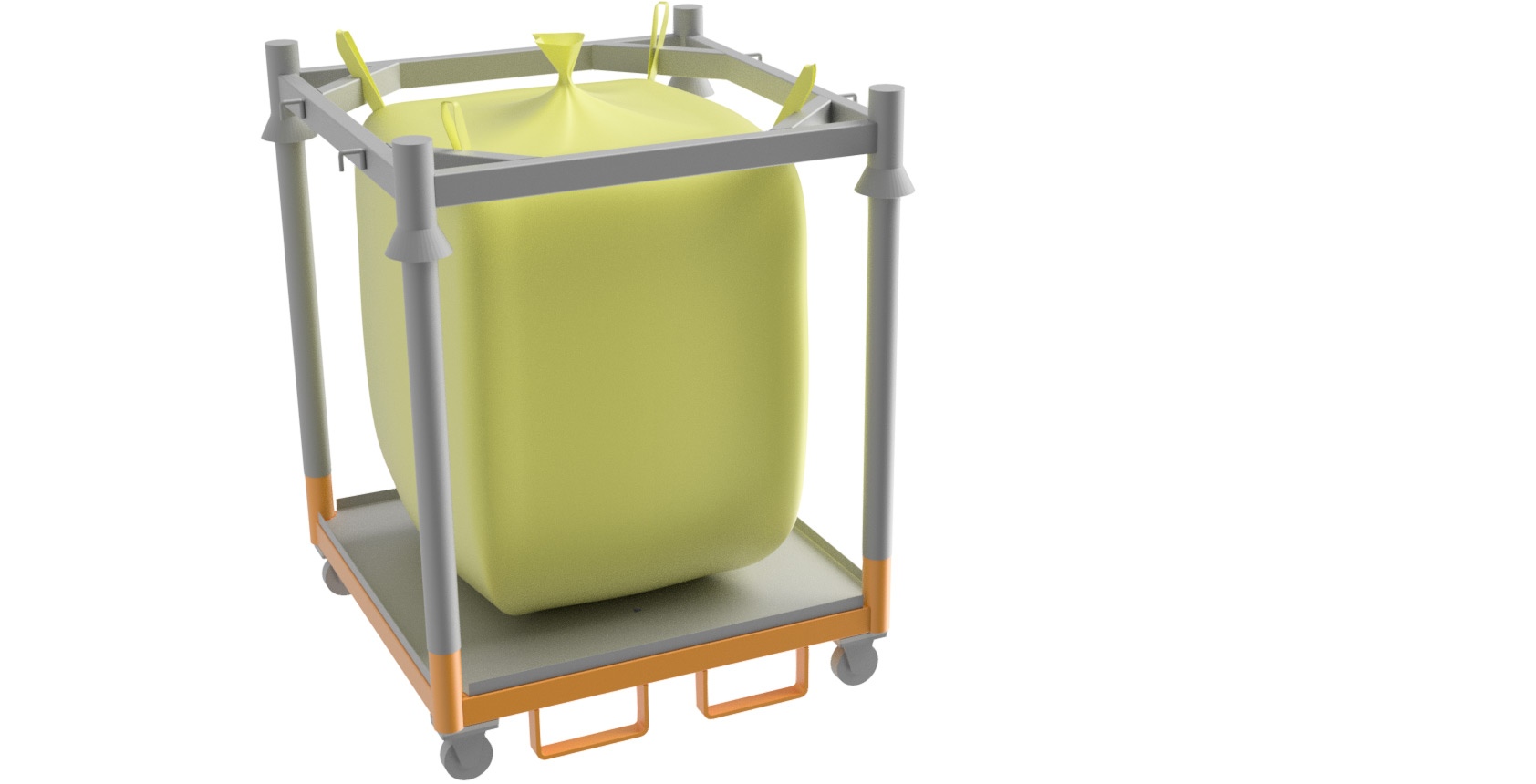

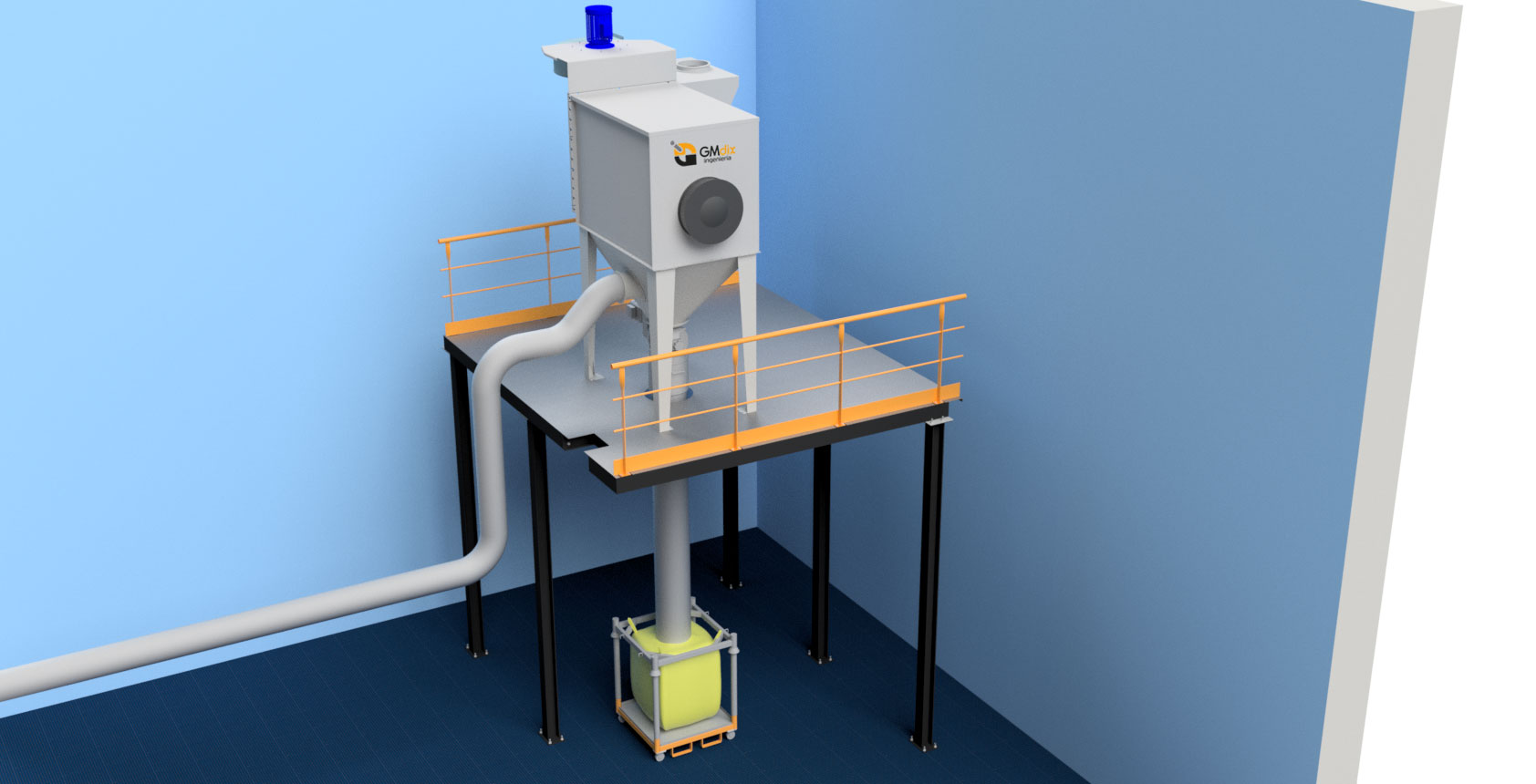

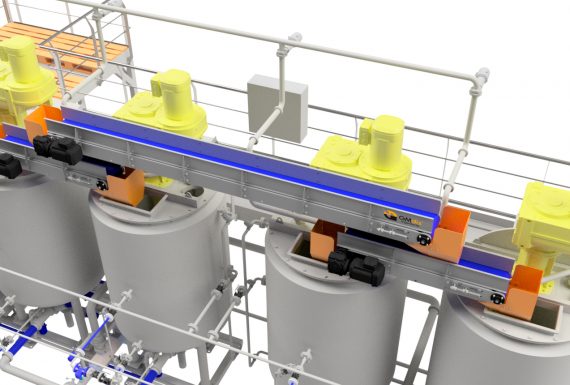

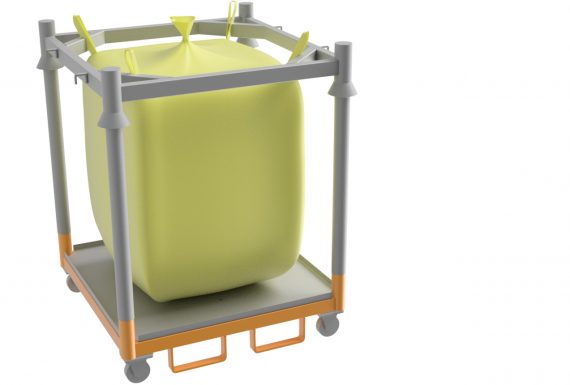

Big-Bag Filling Devices (also called Big-Bag Loading Stations) are equipment used for the effective dust-free filling of bulk solid materials into Big-Bags. It is possible to automate them and even add a weighing and dosing system, making the process efficient. A vibrating system may also be added for product compaction.

Operation

This filling station works by placing the bags at the ends. After filling with air, the product is introduced through an airtight filling nozzle.

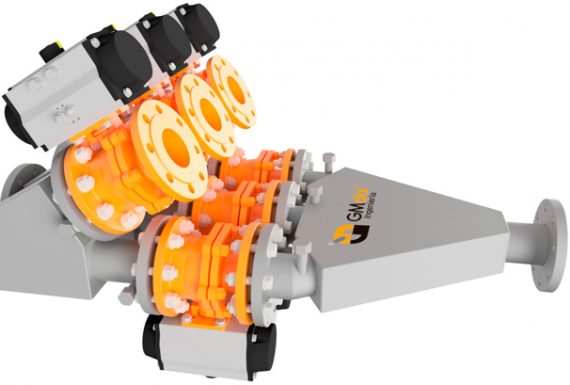

There are different types of filling stations, including: net weight, gross weight, and automated. Different devices may be attached to allow additional functionalities such as bar code reading, automatic bag closing, sampling, etc.

Ventajas

The expansion of this type of Big-Bag container (Flexible Intermediate Bulk Container or FIBC) due to its advantages such as its resistance, price, efficient use of space, possibility of direct printing on the polypropylene fabric, availability of lifting handles, etc. has led to increased purchases of Big-Bag loaders as they are versatile and facilitate different types of filling as well as enabling direct weighing and product compaction.