Solids Conveying

At GMdix Process Engineering, we are experts in the development of complete systems for bulk solids handling. Our services include the design and assembly of industrial installations, as well as the manufacturing of components and equipment for the pneumatic and mechanical conveying of solids.

Types of solids conveying

The solids conveying presents certain difficulties given the great variety of materials. These may be hard, soft, resistant, wet, rubbery, fragile, plastic, adhesive, powder, elastic, etc., so they must be adapted to the different handling and conveying requirements of each.

Pneumatic conveying of bulk solid materials

ELEMENTS THAT COMPRISE A PNEUMATIC CONVEYOR

The objective of the pneumatic conveying of solids is to move bulk solid materials from one point to another by means of a gas current at either positive or negative pressure via piping. Ideal materials for this type of conveying system are dry, fine, bulk materials from microns up to particles of 70 mm or larger. We can convey solids both horizontally and vertically and from a few meters to a maximum of approximately 500 m.

There are four elements that make up a pneumatic conveying system:

Pressure generating element

Conveying line

Solids discharging devices

Solid-gas separator element

Are you looking for a solution for solids and liquids?

Types of pneumatic conveying systems

ACCORDING TO THE PRODUCT TO BE CONVEYED, THE CONVEYING LAYOUT, AND THE CLIENT'S REQUIREMENTS

Pneumatic conveying systems have two sorting mechanisms:

1.- By the concentration of the solid inside the conveying pipe:

– Dilute phase

– Dense phase

2.- By the source of pressure differential generation:

– Vacuum

– Discharge

Each type of system has different applications as explained below.

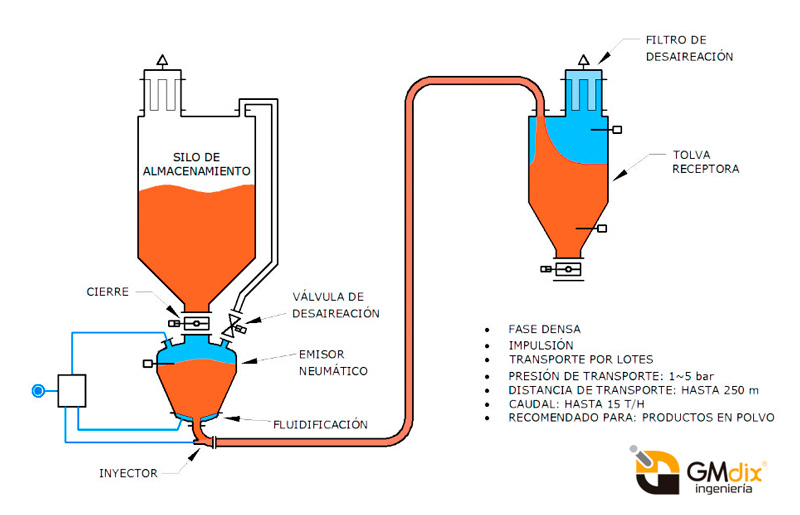

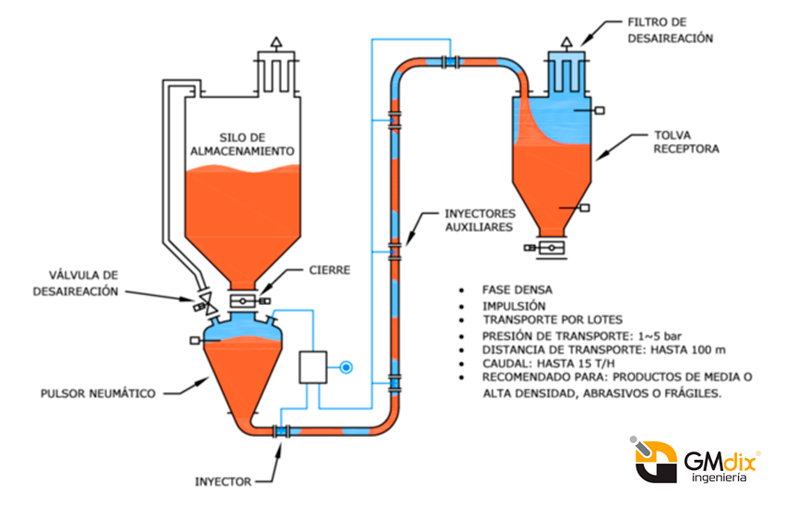

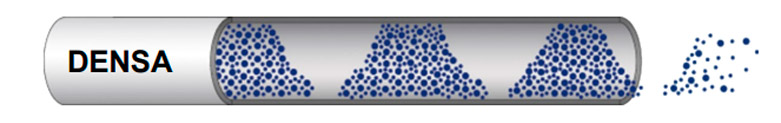

Dense Phase Pneumatic Conveying

Dense Phase Pneumatic Conveying

The volume of air is significantly lower, the solid is conveyed by discharge creating packages, therefore a higher pressure and a significantly lower volume of gas are required. Energy consumption is lower, due to the greater use of the energy transmitted to the gas. The conveying speed is lower, therefore producing less wear. When the solid is abrasive, for example, this is the most recommended mode.

It may be subdivided into fluidised dense phase or packages. At GMdix Process Engineering, we are able to execute each according to the characteristics of the project and the client’s requirements.

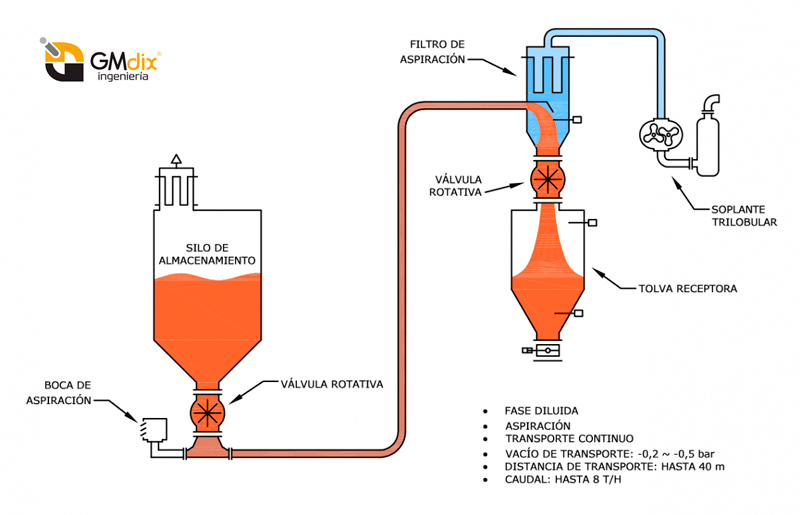

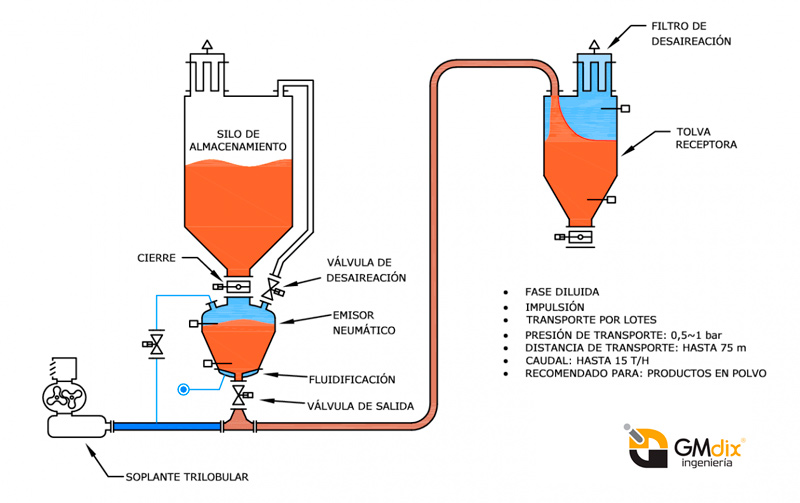

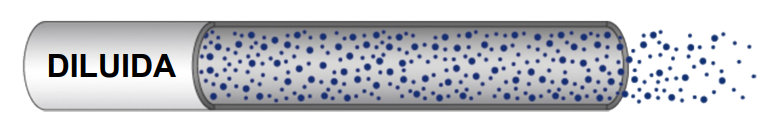

Dilute Phase Pneumatic Conveying

Dilute Phase Pneumatic Conveying

In dilute phase pneumatic conveying, the particles in suspension move through the pipe at high speed with a large amount of low-pressure air. Suitable for conveying low abrasive products.

In this type of pneumatic conveying system, the material is conveyed in suspension inside the pipe. The particles are uniformly distributed throughout the cross-section of the pipe (homogeneous flow). The concentration of solids is relatively low (less than 10 kgs of solids per kg of gas), and the conveying speed is relatively high.

Dilute phase pneumatic conveying is divided into vacuum and discharge.

Transporte neumático en fase diluida en aspiración

Los sistemas neumático en fase diluida por presión negativa o en aspiración son ventajosos cuando necesitamos alimentar un elemento desde diferentes puntos. Se realiza mediante un soplante o bomba de vacío donde el producto es aspirado junto al gas hasta el punto o puntos de destino.

Transporte neumático en fase diluida por impulsión

En el transporte neumático en fase diluida por impulsión o por presión positiva una fuente de generación de aire a presión crea una corriente de gas en la cual estará disuelto el sólido logrando su movimiento desde el punto de origen hasta el punto de destino.

Advantages and disadvantages of pneumatic conveying

USE OF THIS TECHNOLOGY HELPS IMPROVE INTERVENTIONS FOR EACH PROJECT

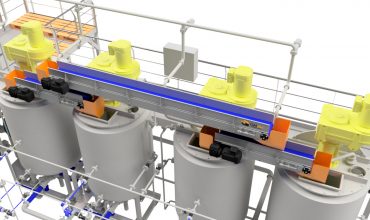

Industrial equipment for solids

SOLUTIONS FOR SOLIDS CONVEYING

Are you looking for a solution for solids and liquids?

Mechanical conveying systems

SOLUTIONS FOR THE MECHANICAL BULK SOLIDS CONVEYING

Mechanical conveying is ideal for feeding or discharging powder or grain products. The materials especially suitable for this type of conveying are fragile, humid, pasty, and susceptible to caking. We manufacture equipment for mechanical conveying, such as through screws and conveyor belts.