Application

This is a processing unit used for the continuous high temperature treatment for short periods and subsequent cooling of products with a low level of acidity (PH greater than 4.5) to kill all pathogenic bacteria and reduce enzymatic activity. This ensures that products such as milk and its derivatives, juices, soft drinks, and prepared foods such as soups, fruits, vegetables, baby food, sauces, tomato-based preparations, and desserts are safe for consumption with a longer shelf life.

The main advantage of this process is the ability to destroy microorganisms, preventing chemical changes in the product.

Operation

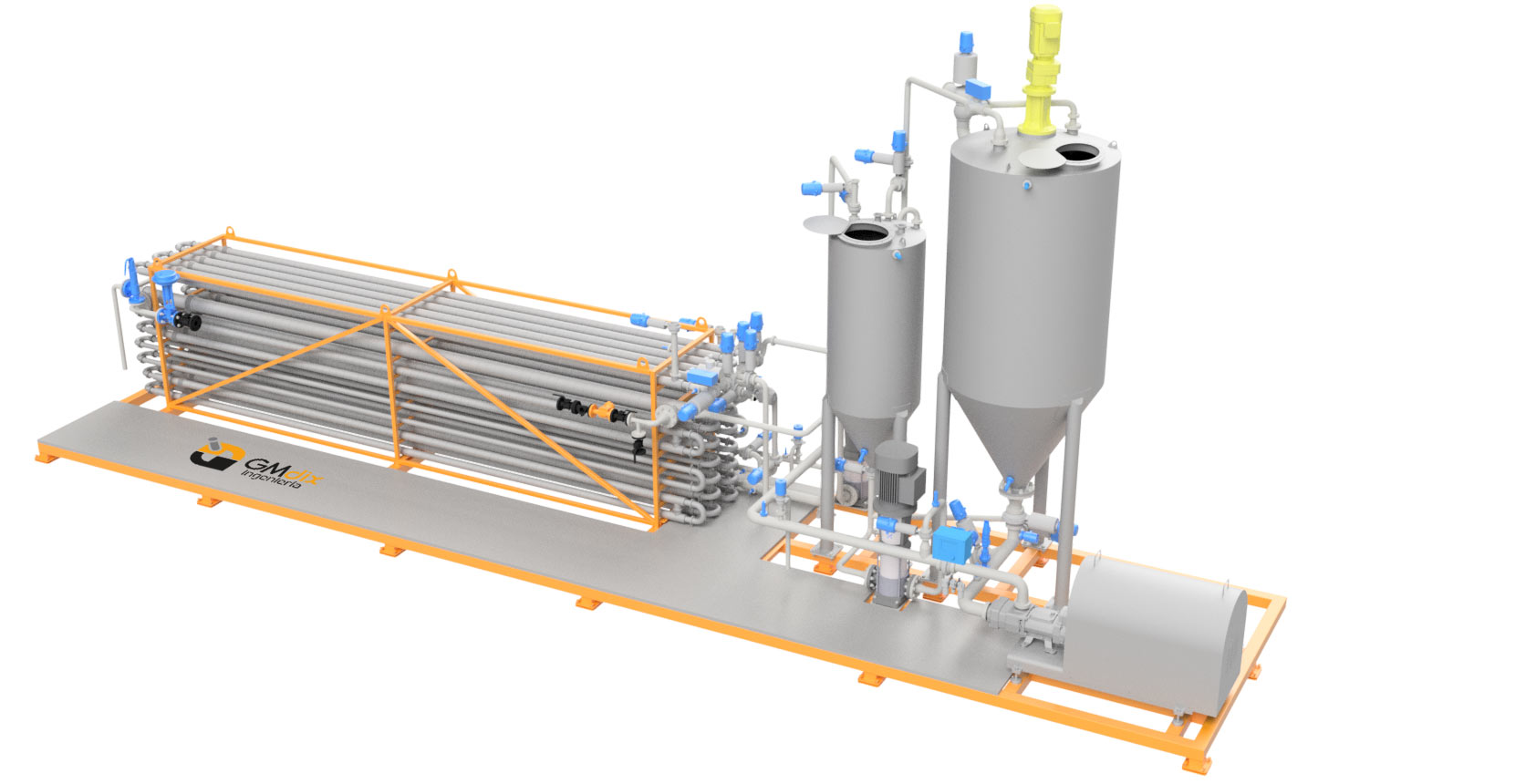

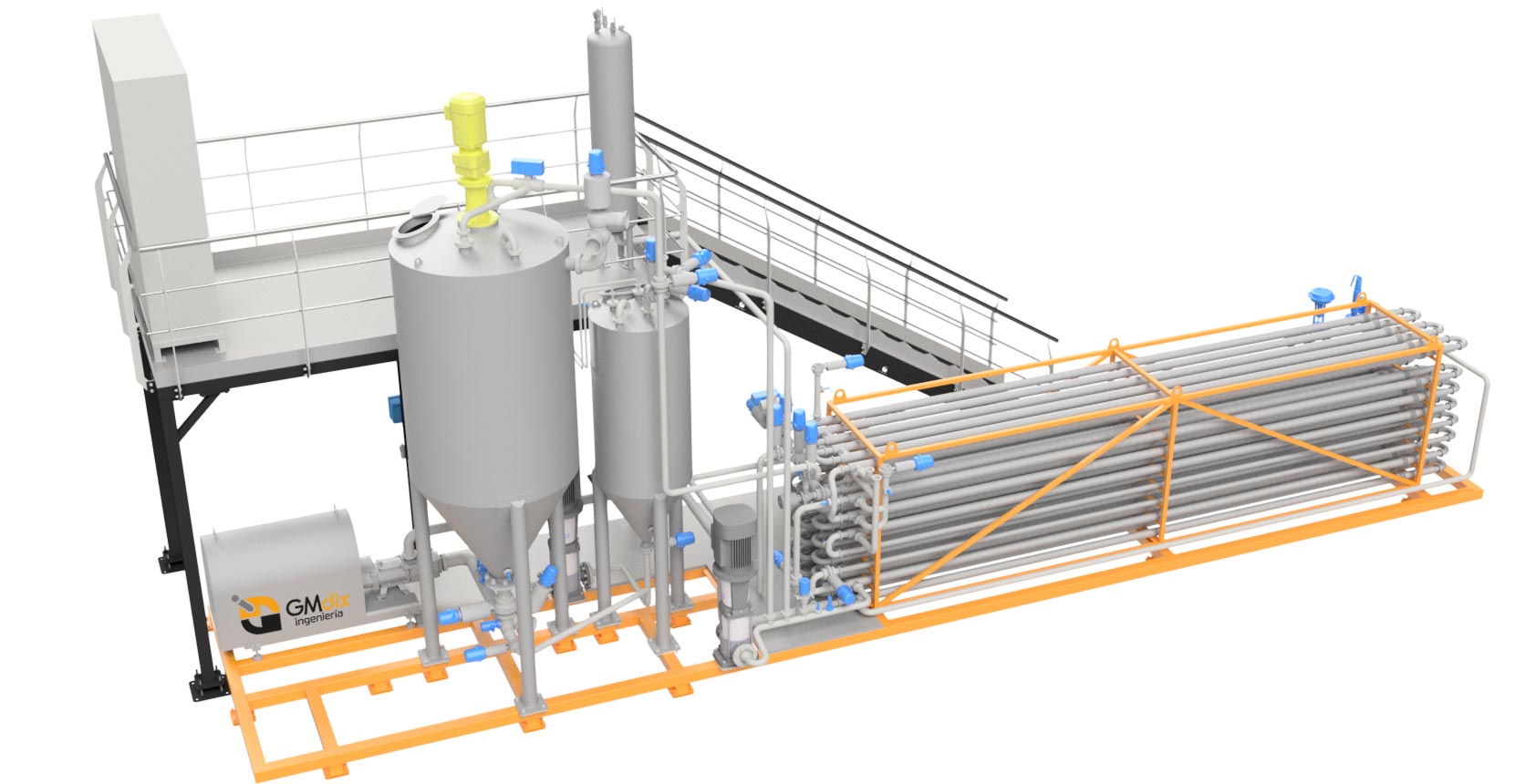

The product is stored in a balance tank or reservoir where a pump conveys it to a plate or tubular exchanger (depending on the product) where it is heated to a pasteurisation temperature depending on the product and/or process requirements.

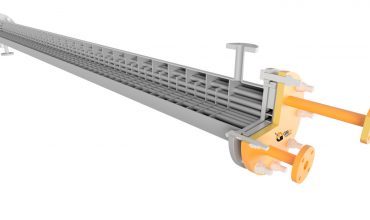

Next, the product is conveyed to the support or retention pipe where it is maintained at the pasteurisation temperature for a period of time to ensure correct pasteurisation.

Finally, the product is conveyed through the cooling stages in which the temperature of the product is reduced to 4ºC, allowing it to be stored.

If the pasteurisation temperature is not reached, the product is recirculated against the reservoir or balance tank, starting the heating process again.

The equipment has a built-in CIP system through which cleaning is carried out after each production, as well as sterilisation at 135ºC prior to use.

In addition, the reactor may be equipped with an economiser to recover the heat at the pasteurisation outlet for reuse at the heating input.

For heating, there is a tubular water/steam exchanger through which the temperatures required for the process are achieved.

Technical characteristics

There are infinite variations given that equipment is adapted to each client’s needs.