Application of melters

Melters are containers used for the melting of raw materials in solid state at room temperature for incorporation into processes in liquid state. For example: melting of margarine for incorporation into automatic confectionery processes; melting of chocolate for food coatings; or melting of paraffins in chemical projects.

Operation

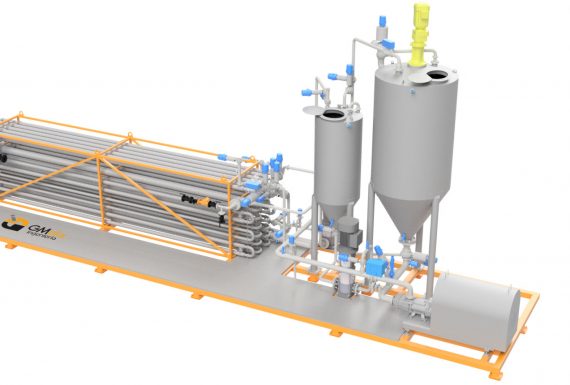

Melters are mainly comprised of a storage container, which may have either a cylindrical or square geometry and may be constructed of different materials, primarily stainless or carbon steel.

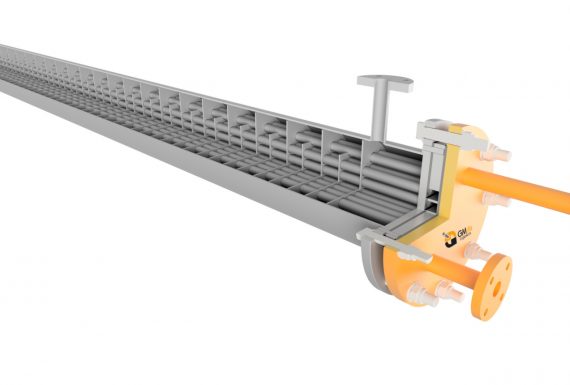

These have a work area in the upper part, which is used as a support for the product to be subsequently poured onto a grate located in the upper part and heated by hot water or steam. This grate is the element that melts the product by conduction, which then precipitates through the grate into the container.

In order to preserve the product state, the container is equipped with a water or steam heating jacket, keeping the melted product in a liquid state until incorporation.

Finally, this industrial equipment incorporates an agitation system to prevent phase separation while enhancing homogenisation of product temperatures.

Technical characteristics

Advantages

Melters enable melting of raw materials prior to incorporation into the process, making it possible to not only reduce the time spent on process mixtures but also to improve them as well. Additionally, melters are widely used in surplus recovery processes (products to be reprocessed).