Application of CIP-SIP

The CIP cleaning system (Cleaning in Place) is an automatic process based on the cleaning of the interior surfaces of pipes, containers, process equipment, filters, and complementary accessories without the need for disassembly. The wash water and detergent solution are circulated through the installation, tanks, fillers, and pipes to ensure consistency and sustainability, ensuring maximum cleanliness and hygiene while minimising the possibility of contamination.

This system offers design versatility and enables process automation, from decentralised units to portable equipment, as well as from one to multiple tanks, to provide the best solution for each application.

The SIP system (Sterilization in Place), also called “Steam in Place”, is an extension of the CIP process that offers additional sterilisation after the CIP process ensuring that no microorganisms remain active in the system.

Operation

The operation consists of circulating a series of cleaning and disinfecting products through the system of process lines and tanks. The solutions are prepared in reservoirs and conveyed through the equipment by means of a closed circuit with a set series of sequences and parametrised times.

Depending on the type of products used to guarantee cleaning, the concentration of these solutions, exposure time, temperature, and turbulence must all be taken into account.

Proper design of the CIP system and the installation is important from the beginning to ensure both cleanliness and drainability.

Technical characteristics

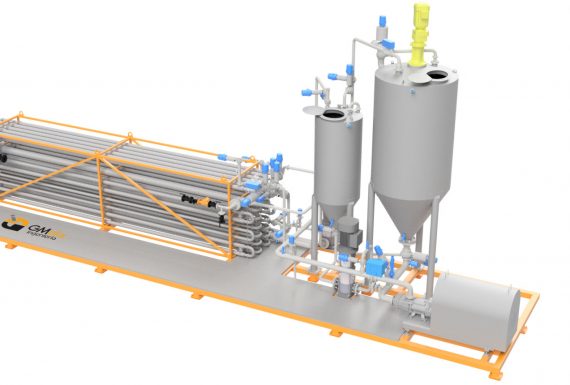

Given that the CIP cleaning system is very versatile in terms of installation, its technical characteristics may vary significantly from one design to another, depending on needs.

A common CIP system is composed of the following elements:

Bedplate

Water and solution preparation tanks with heating

Drive and return pumps controlled by variator

Supply and return lines

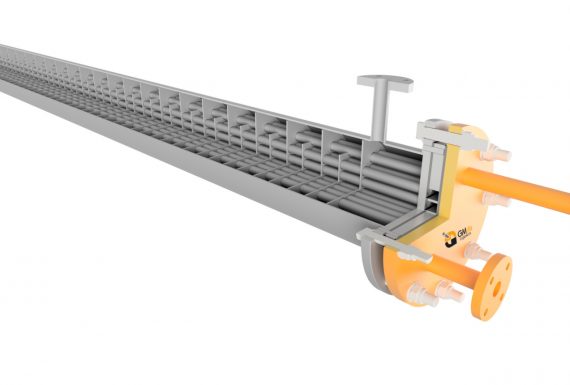

Tubular exchangers

Chemical dosing

Valves (Butterfly, inclined seat, multi-way single seat, etc.)

Tank vent filters

CIP return filters

Instrumentation (levels, flow meters, flow detectors, temperature, pressure, conductivity sensors, etc.)

Gauges

The materials used in these CIP systems are Stainless Steel, EPDM gaskets, and rock wool insulation. All this may be automated, as it is controlled and monitored by a PLC and operated from an HMI or SCADA screen.